01

/05Capability Overview

As the world's largest supplier of turbocharged investment castings, Sinopei Digital Energy Powertrain Division is one of the main businesses of Sinopei Digital Energy at present and one of the main core business segments in the future

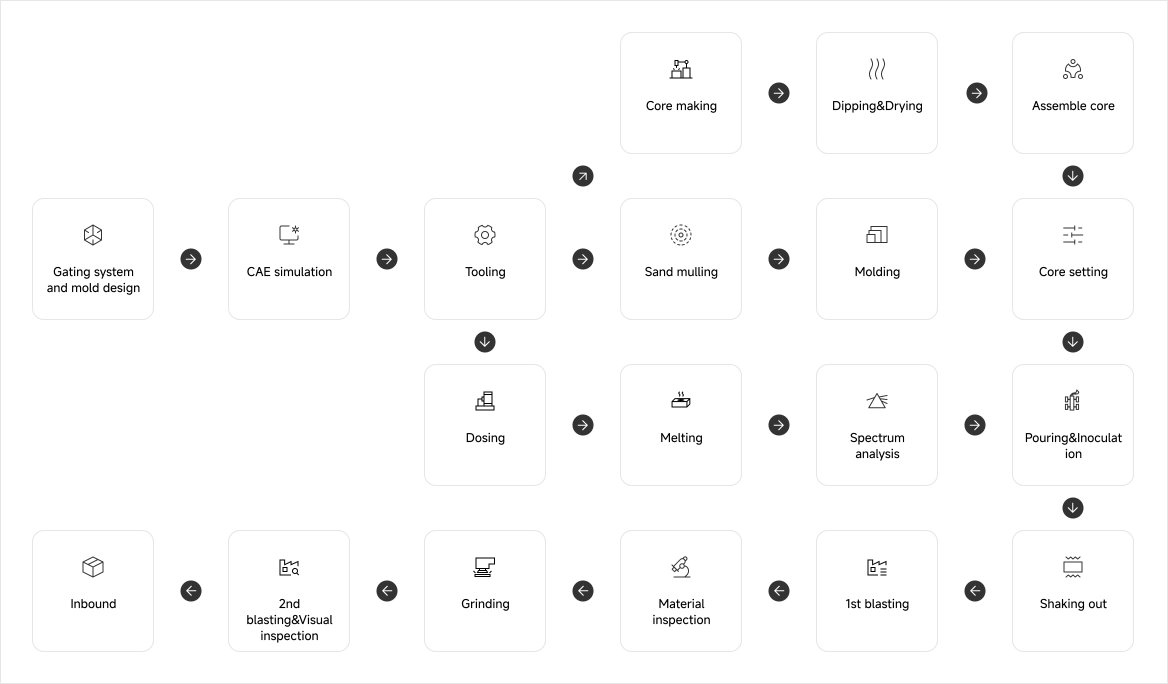

Process introduction

Sinopec Powertrain Division adopts the DISA casting process, which combines the advantages of high precision and high efficiency to ensure the quality and production efficiency of castings. Diversity of materials that can be produced: It can handle a variety of materials, including various grades of ductile iron, gray iron, SiMo ductile iron, etc., and ensure that the castings are strictly controlled and inspected through a strict quality management system to provide customers with value services.

Process

Equipment capabilities

-

Suitable for castingsWeight range:0.1-20kg castings; Maximum size of sand mold:650*535*340

-

Cover the materialVarious grades of gray iron, ductile iron, silicon-molybdenum, ductile iron, etc

-

Linear moulding efficiency200 models/hour (core bottom), 350 models/hour (no core set)

-

Electric furnace capacity4 tons x 4 units; Tapping efficiency:10 tons/hour(3 for 1 backup)

-

Casting capacity2600 tons/month; 530,000 pieces/month (simulated calculation based on 2.5kg/piece intermediate shell product)

-

-

Core making

-

-

Lang Shitai 956 vertical core shooter

-

-

-

Sand core table dry furnace

-

Sand treatment

-

-

DISA Sand Mixer TM2401

-

DISA Sand Mixer TM2402

-

-

Sand treatment moisture content Laboratory and on-line inspection control Compactness Wet compressive strength Breathability temperature MB value

sculpt

-

-

01 DISA moulding machine C3B

-

02 DISA moulding machine C3B

-

-

sculpt Pattern size 650*535*120-340 Capacity (model/hour) 250-350 Cooldown 40~50 Sand shooting, extrusion Top injection, two-way extrusion

smelting

-

-

01Shared intelligent control batching system

-

02Shared intelligent control batching system

-

-

smelting Ingredients in the furnace spectroscopic analysis Effluent temperature Thermometer gun Ingredients spectroscopic analysis White mouth detection In-line detection

Pouring

-

-

01 Bottom pouring machine

-

02 Bottom pouring machine

-

-

Pouring Pouring temperature Thermometer gun Pouring time clock Conceived with the flow Automatic incubation with the flow

Post-processing

-

-

01 Rough shot blasting machine

-

02 Rough shot blasting machine

-

-

-

01 Sand rolling machine

-

02 Sand rolling machine

-

Material capabilities

| material | Detailed grades |

| nodular cast iron | EN-GJS-350-22/LT、EN-GJS-400-18/LT、EN-GJS-400-15、EN-GJS-450-10 、EN-GJS-500-7 、EN-GJS-500-10 EN-GJS-550-5、EN-GJS-600-3、N-GJS-700-2、EN-GJS-800-2 |

| Silicon-molybdenum ductile iron | EN-GJS-SiMo4-06、EN-GJS-SiMo5-10 |

| Gray iron | EN-GJL-150、EN-GJL-200、EN-GJL-250、EN-GJL-300、EN-GJL-350 |

| Isothermal quenched ductile iron | QTD1050-7 |

To learn more about Sinopec's services, contact us now